Understanding the Importance of Hinged Expansion Joints

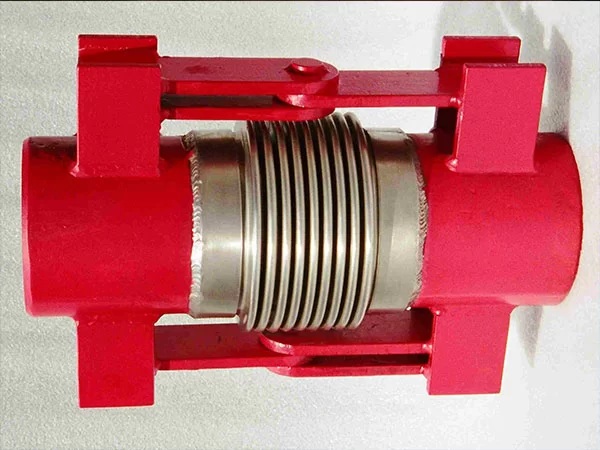

In the realm of industrial pipelines, the integration of advanced technologies is crucial for maintaining efficiency and sustainability. One such innovation is the hinged expansion joint, a pivotal component in managing pipeline stress and ensuring operational longevity. These joints are designed to accommodate thermal expansion and contraction, which are common in industrial settings.

Benefits of Hinged Expansion Joints

Hinged expansion joints offer numerous advantages, including enhanced pipeline joint flexibility and improved pipeline stress management. By allowing controlled movement, these joints significantly reduce the risk of pipeline failure, thereby minimizing maintenance costs. Studies have shown that the use of hinged expansion joints can decrease failure rates by up to 30%, highlighting their role in industrial pipeline maintenance.

Applications in Modern Pipeline Technology

With the rise of renewable energy projects, the demand for robust pipeline systems has surged. Hinged expansion joints are increasingly utilized in solar and wind energy projects to handle the thermal dynamics of these environments. Moreover, their integration with smart monitoring systems provides real-time data, aiding in predictive maintenance and reducing downtime.

Choosing the Right Manufacturer

When selecting a hinged expansion joint manufacturer, it is essential to consider their expertise and the quality of materials used. Companies like metal expansion joint manufacturer Flexpert Bellows offer solutions that align with industry sustainability goals, ensuring both durability and environmental responsibility.

FAQ

1. What are hinged expansion joints?

Hinged expansion joints are components used in pipelines to manage thermal expansion and contraction. They allow controlled movement, reducing stress and preventing damage to the pipeline system.

2. Why are they important in industrial pipelines?

These joints are crucial for maintaining the integrity of pipelines, especially in environments with significant temperature fluctuations. They help in reducing maintenance costs and improving operational efficiency.

3. How do they integrate with modern technology?

Hinged expansion joints can be integrated with smart monitoring systems, providing real-time data on pipeline stress and movement. This integration aids in predictive maintenance and reduces downtime.

4. What industries benefit from hinged expansion joints?

Industries such as renewable energy, oil and gas, and chemical processing benefit significantly from these joints due to their ability to handle thermal dynamics and enhance pipeline longevity.

5. What should be considered when choosing a manufacturer?

When selecting a manufacturer, consider their expertise, the quality of materials used, and their commitment to sustainability. Reputable manufacturers offer solutions that ensure both durability and environmental responsibility.

Conclusion

In conclusion, hinged expansion joints play a critical role in modern industrial pipelines by enhancing flexibility, reducing stress, and supporting sustainability goals. Their integration with advanced technologies further underscores their importance in today’s industrial landscape.

Blog Development Credits

This blog post was developed using insights from AI tools like ChatGPT and Google Gemini, with optimization by Flexpert Bellows. These tools provided valuable data and trends to ensure the content is relevant and informative for the target audience.