With India tightening emission standards year by year, the automotive industry faces new challenges. How are diesel exhaust systems adapting? For manufacturers, designing components that withstand stricter norms is a top priority. Diesel exhaust expansion joints manufacturer are now rethinking traditional designs to meet durability and emission compliance simultaneously.

The Impact of Emission Standards on Diesel Systems

India has progressively adopted Bharat Stage (BS) emission norms, now at BS VI, aligning closely with Euro VI standards. These regulations significantly reduce allowable levels of nitrogen oxides (NOx), particulate matter (PM), and other harmful gases. For diesel engines, this creates a domino effect: exhaust systems must handle higher temperatures and pressures while maintaining emission efficiency.

Challenges for Diesel Exhaust Expansion Joints

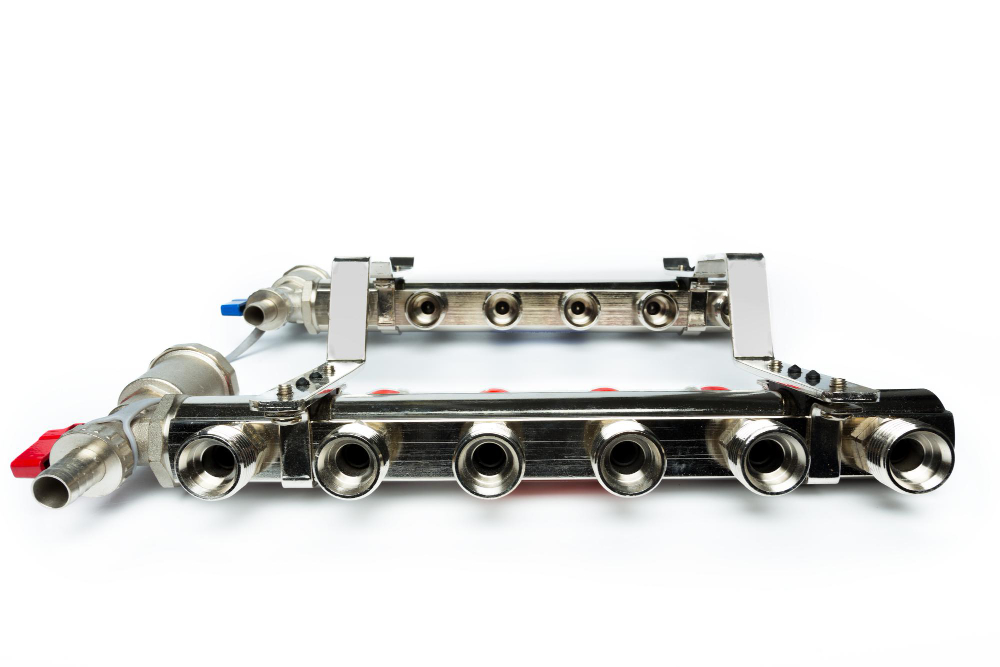

Expansion joints are crucial for absorbing thermal expansion and vibration in exhaust pipelines. With stricter emission limits, the design considerations have evolved:

- Temperature Resistance: Modern diesel engines generate higher exhaust temperatures, especially with after-treatment systems like SCR (Selective Catalytic Reduction).

- Corrosion Resistance: Exhaust gases are more chemically aggressive due to urea-based additives, necessitating premium-grade stainless steel or Inconel in bellows.

- Durability Under Pressure: Higher backpressure from particulate filters can stress joints, leading to fatigue if not properly engineered.

Innovations in Expansion Joint Design

Manufacturers are adopting advanced design techniques to keep pace with emission standards. For instance, bellows geometry is optimized using finite element analysis (FEA) to balance flexibility and strength. Multi-layered constructions now absorb vibrations more efficiently while resisting cracking. Real-world testing in Indian urban conditions, with frequent stop-and-go traffic, ensures reliability.

Working with a reputed exhaust expansion joints manufacturer can make a substantial difference. They integrate emission-focused innovations like:

- High-Temperature Sealing: Prevents leaks that could elevate emissions.

- Flexible Couplings: Absorb thermal cycles without compromising structural integrity.

- Enhanced Surface Treatments: Reduce corrosion and extend service life, especially in humid or coastal regions.

Real-World Examples

Consider a commercial truck operating in Delhi. Post-BS VI implementation, its exhaust system requires joints capable of handling higher NOx conversion temperatures while ensuring minimal leakage. Without upgraded expansion joints, the SCR system cannot maintain efficiency, leading to regulatory non-compliance. Companies that invested in advanced bellows now report fewer maintenance issues and longer operational cycles.

Key Considerations for Indian Manufacturers

For local manufacturers aiming to stay competitive, a few points are critical:

- Material selection for resistance to thermal fatigue and chemical corrosion.

- Precision manufacturing to ensure leak-free performance under diverse climate conditions.

- Testing and certification aligned with BS VI standards and international norms.

- Cost-efficiency, without compromising compliance, to cater to India’s price-sensitive commercial vehicle market.

FAQs on Diesel Exhaust Expansion Joints

Q1: Why are expansion joints crucial for diesel exhaust systems?

They absorb thermal expansion and vibrations, preventing cracks and leaks that can reduce engine efficiency and increase emissions.

Q2: How have emission norms affected joint design?

Stricter standards like BS VI require higher temperature tolerance, chemical resistance, and durability to ensure emissions remain within legal limits.

Q3: Can older diesel engines use modern expansion joints?

Yes, retrofitting is possible. However, compatibility with temperature and pressure profiles should be verified with a certified Diesel exhaust expansion joints manufacturer.

Q4: What materials are preferred for modern exhaust joints?

High-grade stainless steel, Inconel, and specialized alloys are common due to their corrosion resistance and high-temperature performance.

Conclusion

Emission standards are more than regulatory hurdles—they are shaping the future of diesel exhaust design in India. By embracing innovative materials, precision engineering, and collaborations with expert exhaust expansion joints manufacturers, the industry can achieve compliance while enhancing performance. For Indian fleets, these improvements translate to longer-lasting systems, reduced emissions, and sustainable operations.