In industrial applications, managing thermal movement and vibration is crucial for maintaining system integrity and performance. One of the most effective solutions for addressing these challenges is the use of lateral expansion joints. These components play a vital role in accommodating the physical changes that occur in piping systems due to temperature fluctuations and mechanical vibrations.

Understanding Thermal Movement

Thermal movement refers to the expansion and contraction of materials as temperatures change. In piping systems, this can lead to significant stress if not properly managed. Thermal expansion joints are designed to absorb these movements, preventing damage and ensuring the longevity of the system.

How Lateral Expansion Joints Function?

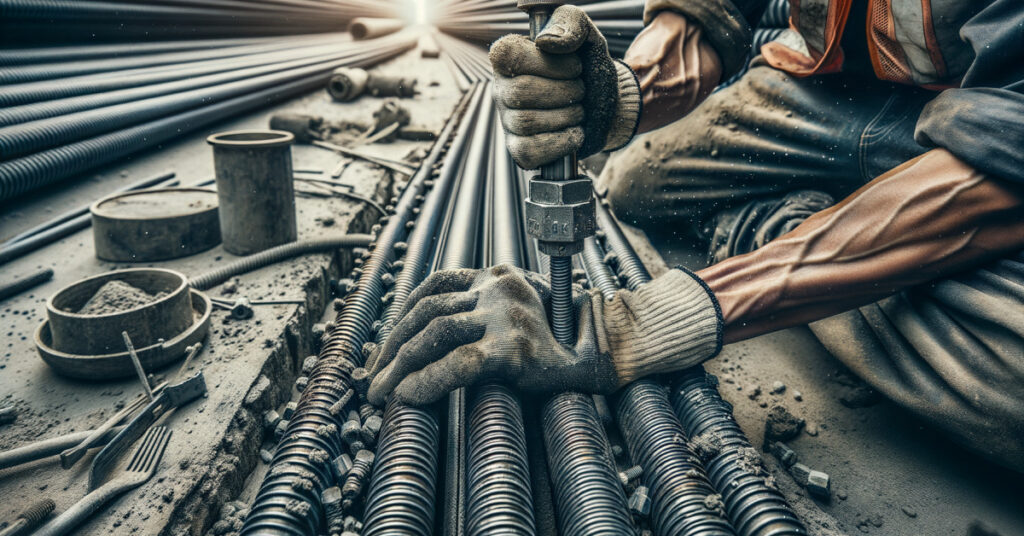

Lateral expansion joints are specifically engineered to accommodate lateral displacement in piping systems. They consist of flexible materials that allow for movement while maintaining a seal against leaks. This flexibility is essential for managing thermal stress and ensuring that the system operates smoothly under varying conditions.

Key Applications of Lateral Expansion Joints

- Pipeline Systems: Used extensively in oil and gas pipelines to manage thermal expansion and prevent structural damage.

- HVAC Systems: Helps in vibration control and thermal movement in heating and cooling systems.

- Industrial Machinery: Essential for maintaining the integrity of machinery that experiences thermal fluctuations.

Vibration Control in Piping

In addition to thermal movement, vibration control is another critical aspect of piping system design. Vibration isolation techniques are employed to reduce the transmission of vibrations from machinery to the piping system. This not only protects the integrity of the pipes but also enhances overall system performance.

Real-World Example:

In a recent project involving a large manufacturing facility, engineers implemented vibration damping systems alongside lateral expansion joint in India. The result was a significant reduction in mechanical failures and maintenance costs, demonstrating the effectiveness of these components in real-world applications.

Current Trends in Expansion Joint Technology

The industry is witnessing several trends that are shaping the future of expansion joint design. Key developments include:

- Increased Use of Advanced Materials: Manufacturers are utilizing high-performance materials like elastomers and composites to enhance durability.

- Integration of Smart Technology: The incorporation of IoT technology allows for real-time monitoring, enabling predictive maintenance.

- Sustainability Focus: A growing emphasis on eco-friendly manufacturing processes is evident as businesses aim to reduce their environmental impact.

Managing Thermal Stress

Effective management of thermal stress is essential for preventing costly downtime and mechanical failures. A study indicates that approximately 70% of mechanical failures in piping systems stem from inadequate thermal expansion management. Investing in high-quality lateral expansion joints can significantly mitigate these risks.

Challenges in Implementation

Despite the benefits, businesses often face challenges in cost management. Balancing the initial investment in high-quality expansion joints with the long-term benefits of reduced maintenance and increased operational efficiency is crucial. Companies must evaluate their needs and consider the potential savings in downtime and repairs.

FAQs

1. What are lateral expansion joints?

Lateral expansion joints are flexible components used in piping systems to accommodate lateral movement caused by thermal expansion and contraction. They help maintain system integrity and prevent leaks.

2. How do expansion joints help in vibration control?

Expansion joints are designed to absorb vibrations and thermal movements in piping systems. By isolating vibrations, they protect the integrity of the pipes and enhance overall system performance.

3. What materials are commonly used in lateral expansion joints?

Common materials include elastomers, metals, and composites. These materials are selected based on their ability to withstand thermal and mechanical stresses while providing flexibility.

4. How can I monitor the performance of expansion joints?

Integrating IoT technology and sensors allows for real-time monitoring of expansion joint performance. This enables predictive maintenance, reducing downtime and maintenance costs.

5. What industries use lateral expansion joints?

Lateral expansion joints are widely used in industries such as oil and gas, HVAC, and manufacturing. They play a critical role in maintaining the integrity of piping systems across various applications.

Conclusion

In summary, lateral expansion joints are essential components for managing thermal movement and vibration in piping systems. By investing in high-quality solutions, businesses can enhance operational efficiency, reduce maintenance costs, and ensure the longevity of their systems.

Blog Development Credits

This blog post was developed with insights from AI tools like ChatGPT and Google Gemini, and optimized by Flexpert Bellows.