In global piping and process industries, choosing the right expansion joint supplier often feels like a balancing act between quality, cost, and reliability. Interestingly, more EPC contractors and plant operators are turning their attention to India. Why? Because Indian manufacturers have quietly built a reputation for delivering universal expansion joints that perform reliably in some of the toughest industrial environments.

Today, working with a trusted universal expansion joints manufacturer in India is no longer just a cost decision it’s a strategic one driven by engineering depth and manufacturing maturity.

A Strong Foundation in Engineering Expertise

India’s strength in mechanical and industrial engineering is no accident. The country produces a large pool of technically trained engineers each year, many of whom specialize in thermal systems, pressure vessels, and piping design. According to data from the All India Council for Technical Education (aicte-india.org), India consistently ranks among the top nations for engineering graduates.

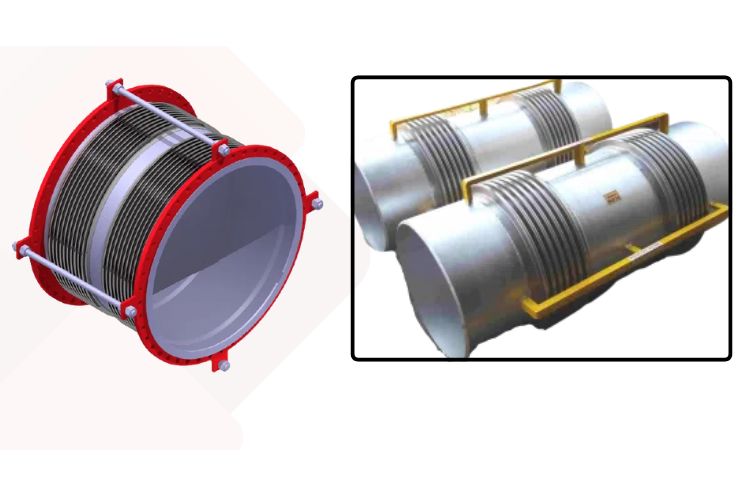

This talent advantage translates directly into better-designed universal expansion joints units that handle axial, lateral, and angular movements without overstressing the piping system.

Manufacturing Quality That Meets Global Standards

One common misconception is that affordability comes at the cost of quality. In reality, many Indian manufacturers follow international standards such as ASME, EJMA, and ISO as part of their daily operations. Quality control processes are no longer optional they are expected.

What global buyers typically notice:

- Consistent material traceability and documentation

- Advanced testing for pressure, fatigue, and movement cycles

- Customization without long lead times

This level of discipline makes Indian suppliers competitive not just in Asia, but across Europe, the Middle East, and North America.

Cost Efficiency Without Compromising Performance

Let’s be honest cost still matters. According to a World Bank manufacturing competitiveness overview (worldbank.org), India benefits from lower operational costs while maintaining improving productivity levels. This allows manufacturers to price products competitively without cutting engineering corners.

For large-scale projects where dozens or hundreds of expansion joints are required, these savings can significantly impact overall project budgets.

Customization as a Standard, Not an Exception

Unlike mass-produced components, universal expansion joints are rarely “one-size-fits-all.” Indian manufacturers excel here, offering design flexibility based on pressure ratings, temperature ranges, media type, and space constraints.

Midway through many projects, EPC contractors realize the value of working with a responsive universal joint bellows manufacturer that can adapt designs quickly without restarting the entire approval cycle.

Industry Experience Across Diverse Sectors

Indian manufacturers serve a wide range of industries, from power generation and oil & gas to chemicals and desalination plants. This cross-sector exposure builds practical knowledge that goes beyond theory.

For example, understanding corrosion patterns or pressure fluctuations in petrochemical environments becomes easier when manufacturers have firsthand experience. Resources like How Industrial Bellows Work for Chemical and Petrochemical Plants highlight how application-specific insights improve expansion joint performance.

Faster Lead Times and Reliable Support

Another subtle advantage is agility. Indian manufacturers are often more flexible with production scheduling and design iterations. This responsiveness can be critical when projects face unexpected changes or tight commissioning deadlines.

Buyers often value:

- Shorter manufacturing and delivery cycles

- Direct access to engineering teams

- After-sales technical support during installation

These practical benefits help reduce on-site delays and installation risks.

Frequently Asked Questions

1. Why are Indian manufacturers competitive globally?

They combine skilled engineering talent, efficient manufacturing processes, and cost advantages while adhering to international quality standards.

2. Do Indian expansion joints meet international codes?

Yes. Most reputable manufacturers design and test universal expansion joints according to ASME, EJMA, and ISO guidelines.

3. Are customized designs easily available?

Customization is a core strength. Indian manufacturers routinely tailor expansion joints to specific operating conditions and project requirements.

4. Which industries commonly source from India?

Power plants, oil & gas facilities, chemical and petrochemical units, and large infrastructure projects frequently source from Indian suppliers.

Final Thoughts

The growing preference for Indian manufacturers isn’t driven by price alone. It’s the combination of engineering competence, manufacturing discipline, customization capability, and dependable support that sets them apart. For universal expansion joints, India has evolved from an alternative option to a trusted global partner.